Precision Fabrication Services

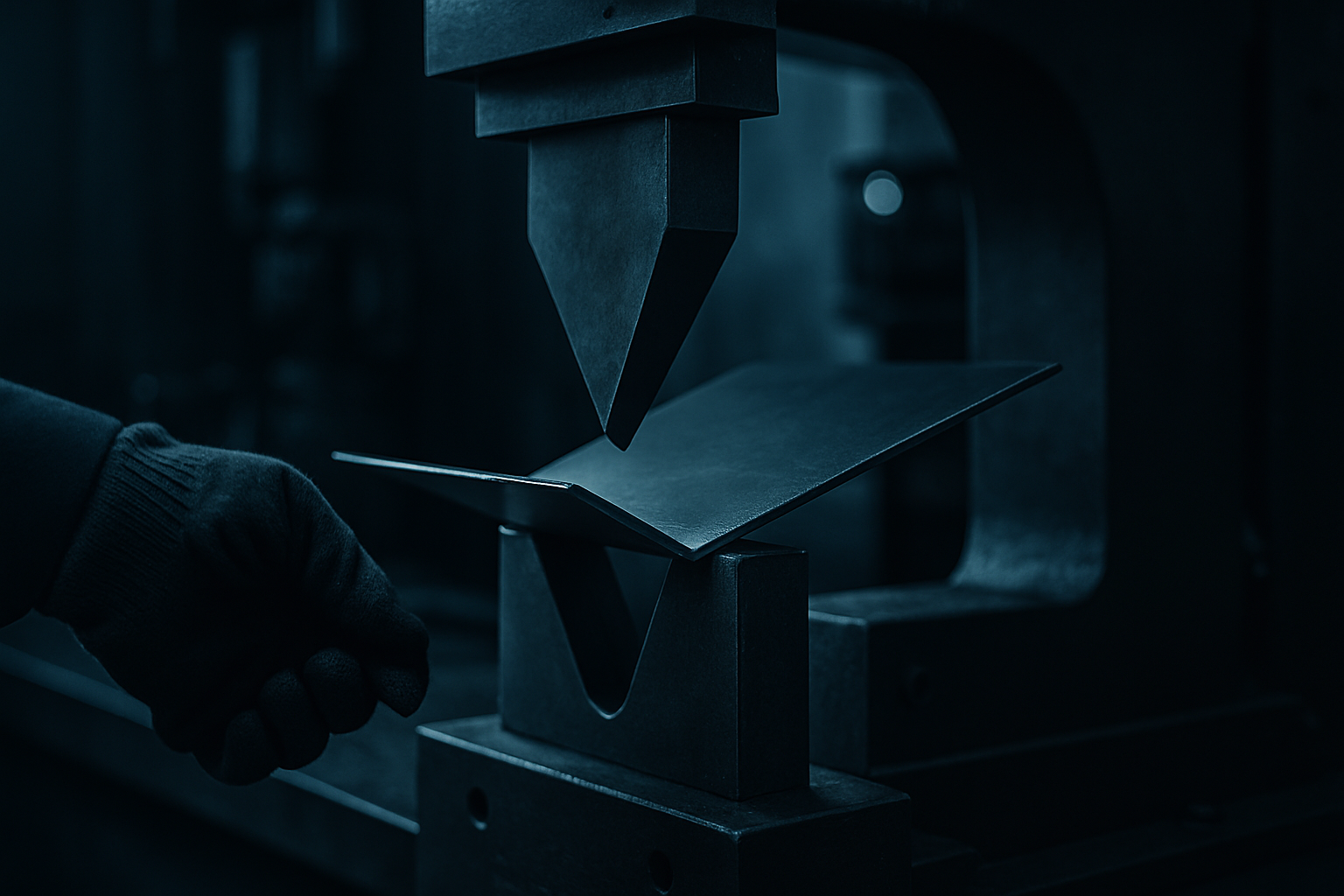

Custom metal fabrication solutions with accuracy, strength, and modern techniques.

At MFC, our fabrication shop delivers complete metal fabrication solutions, from cutting and welding to full structural assembly. We turn raw metal into functional structures and precision-built products, meeting the highest standards in durability, strength, and finish.

1. Complete Metal Fabrication Services

We handle the full fabrication cycle in-house, including cutting, bending, welding, drilling, assembling, and finishing, offering our clients fast and flexible solutions.

2. Advanced Tools & Machinery

Our facility includes:

- CNC Plasma Cutting Machines

- Hydraulic Press Brakes

- Welding Stations (MIG, TIG, Stick)

- Rollers, Shears, and Angle Cutters

- Drill Presses and Workbenches

This allows us to fabricate both light and heavy structures with accuracy and consistency.

3. Supported Materials

We work with a wide range of metals including:

- Mild Steel

- Stainless Steel

- Galvanized Sheets

- Aluminum

- Alloy Steel

We select materials based on structural needs, environment, and client application.

4. Structural & Custom Products

We fabricate:

- Industrial Frames & Platforms

- Steel Structures

- Cabinets, Enclosures & Racks

- Architectural Metal Fixtures

- Custom Brackets, Mounts & Supports

All parts are built to drawing, prototype, or concept.

5. Capacity & Projects

We fabricate items from 1mm sheets to 25mm plates, and frames from 1kg to 1 ton, covering:

- Industrial Installations

- Warehousing Systems

- Site Infrastructure

- Custom Engineering Projects

6. Skilled Welding & Assembly

Our certified welders use MIG, TIG, and Arc welding techniques to assemble strong, leak-proof joints. Assemblies are tested for integrity and fit before delivery.

7. Technical Drawings & Prototyping

We assist clients in turning hand sketches, 2D drawings, or 3D CAD models into working fabricated units, with prototyping support where needed.

8. Surface Finishing Options

Fabricated parts can be delivered with primer, powder coating, or hot-dip galvanizing, offering protection and a finished appearance.

9. Quality Checks & Load Testing

Every product is inspected for dimensional accuracy, welding strength, and structural integrity, with load tests performed for critical components.

10. Build with Confidence

From design to delivery, MFC is your full-cycle fabrication partner, ready to meet industrial and custom metalwork demands at scale.

Related Posts

RUBBER MOULDING

MAINTENANCE SERVICES

FOUNDRY WORKS

METAL SHEET PRESS WORK

PLATING & ELECTROPLATING

PAINT SHOP & POWDER COATING

MACHINE SHOP

FABRICATION SHOP