Industrial Heat Treatment Services

Enhancing metal properties through precision-controlled heating processes.

At MFC, we provide specialized heat treatment services to enhance the mechanical properties of metals, increasing hardness, strength, and resistance. Our treatments are tailored to meet specific performance requirements, ensuring your components last longer and perform better under stress.

1. Full-Spectrum Heat Treatment Services

We offer a complete range of heat treatment processes including:

- Annealing

- Normalizing

- Hardening & Tempering

- Quenching (Oil & Water)

- Stress Relieving

Each process is selected based on the material type and functional demands of the component.

2. Materials We Treat

We apply heat treatment to a wide variety of ferrous and non-ferrous metals such as:

- Carbon Steel

- Alloy Steel

- Tool Steel

- Stainless Steel

- Cast Iron

- Copper Alloys

Each alloy is treated using precise temperature cycles and controlled cooling methods to achieve optimal properties.

3. Property Enhancement & Benefits

Our treatments help achieve:

- Increased wear resistance

- Improved machinability

- Enhanced ductility or toughness

- Refined grain structure

- Reduced internal stresses

These improvements extend component life and allow for more efficient manufacturing and usage.

4. Controlled Processes & Monitoring

We use digital furnaces with real-time monitoring to maintain exact temperatures and time cycles, ensuring consistency and repeatability across batches.

5. Applications Across Industries

Our treated parts are used in:

- Power Transmission

- Oil & Gas Equipment

- Gears & Shafts

- Tooling & Molds

- Machinery Components

- Automotive & Aerospace

6. Customized Solutions Per Project

Every material and application has unique demands. We offer tailored heat treatment cycles depending on hardness targets, grain structure, and finishing methods.

7. Post-Treatment Machining & Inspection

After treatment, we offer CNC finishing, deburring, and dimensional inspection to ensure final accuracy and readiness for installation.

8. Quality Assurance & Certification

Each batch is tested for hardness (HRC, HB), microstructure, and dimensional distortion, with full documentation and traceability when required.

9. Batch & Job-Order Flexibility

We handle both small and large quantities with fast turnaround, ideal for everything from custom orders to mass production requirements.

10. Strengthen with Confidence

Trust MFC’s heat treatment expertise to transform your raw materials into performance-driven components, built to withstand the toughest conditions.

Related Posts

RUBBER MOULDING

MAINTENANCE SERVICES

FOUNDRY WORKS

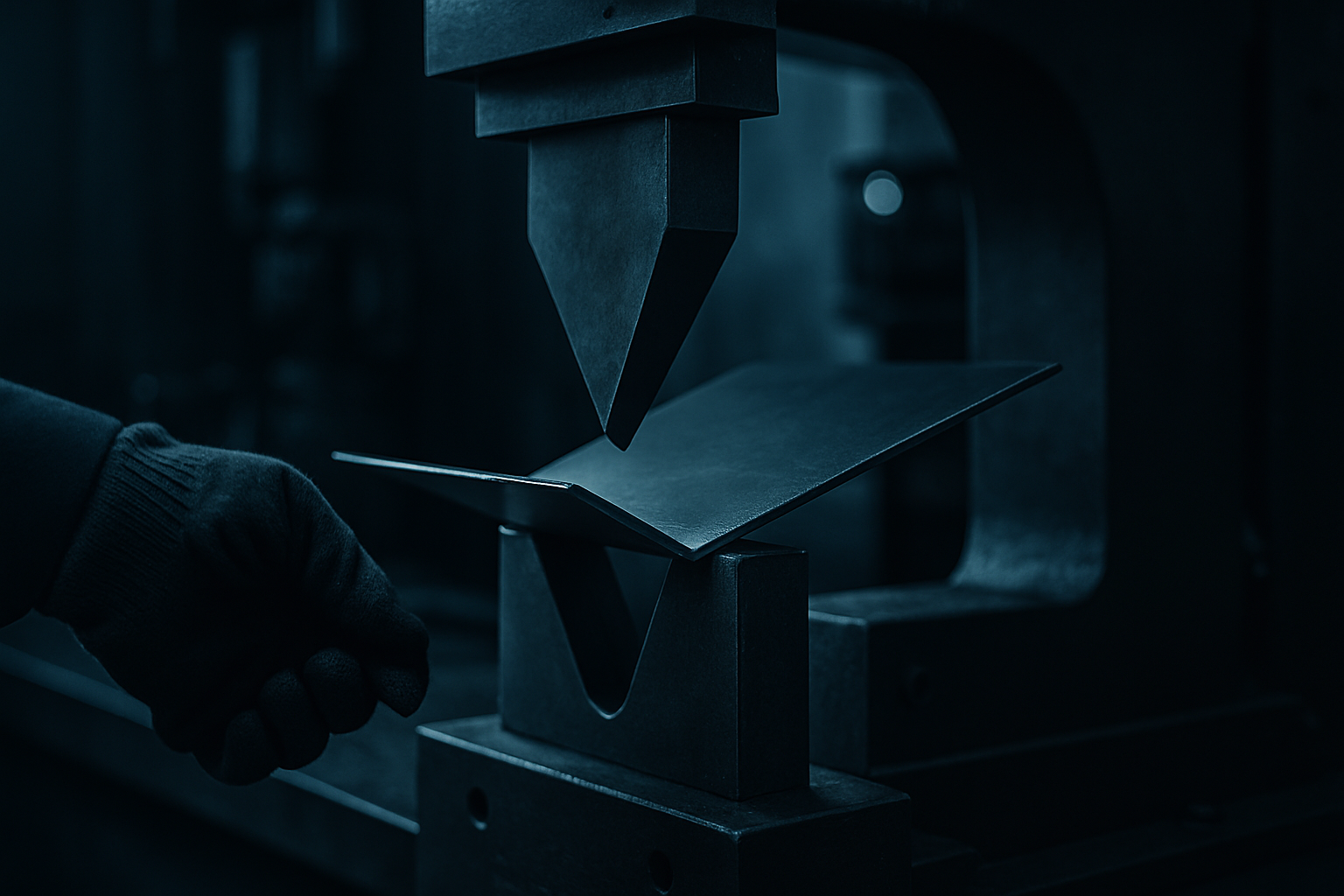

METAL SHEET PRESS WORK

PLATING & ELECTROPLATING

PAINT SHOP & POWDER COATING

MACHINE SHOP

FABRICATION SHOP