Reliable Foundry Solutions

Expert casting services using advanced molding and metal pouring technology.

At MFC, our foundry division delivers high-quality cast components for diverse industrial applications. We specialize in both ferrous and non-ferrous castings, offering dimensional precision, material versatility, and superior surface finish across a wide range of production volumes.

1. Full-Range Metal Casting Capabilities

We manufacture cast components using ferrous, non-ferrous, and alloy metals, tailored for industries requiring high mechanical strength, corrosion resistance, and dimensional accuracy.

2. Multiple Casting Techniques

Our foundry is equipped to handle a variety of casting processes including:

- Sand Casting

- Gravity Die Casting

- Pressure Die Casting

- Centrifugal Die Casting (Vertical & Horizontal)

- Shell Mould Casting

- Investment Casting

3. Precision & Complexity in Shape

From basic blocks to intricate, multi-core geometries, our casting team delivers highly precise and complex components ready for machining or direct assembly.

4. Alloy Casting Expertise

We work with a variety of advanced metal alloys including nickel-based, aluminum, copper, and high-performance stainless steel alloys. These are ideal for applications involving extreme temperatures, pressure, or chemical exposure.

5. Capacity & Applications

Our foundry handles parts from 100 grams to 50 kilograms, serving industries like:

- Industrial Machinery

- Automotive & Transportation

- Oil & Gas

- Pumps & Valves

- Construction & Infrastructure

6. Post-Casting Treatments

To meet exact specifications, we offer heat treatment, surface cleaning, deburring, and CNC machining, delivering finished parts with enhanced mechanical properties.

7. Quality Assurance Process

Each casting is subjected to visual inspection, dimensional checks, NDT testing, and chemical analysis, ensuring full compliance with international standards.

8. Tooling & Prototyping Support

We assist clients with tool design, pattern development, and prototype casting to ensure alignment between expectations and output before mass production.

9. Foundry Experience That Counts

With decades of know-how, modern furnaces, and an experienced metallurgical team, MFC stands out as a reliable foundry partner across the region.

10. Let’s Shape Your Idea

From a 3D model to a production-ready part, we turn your casting concepts into functional, high-quality components. Reach out for a custom consultation.

Related Posts

RUBBER MOULDING

MAINTENANCE SERVICES

FOUNDRY WORKS

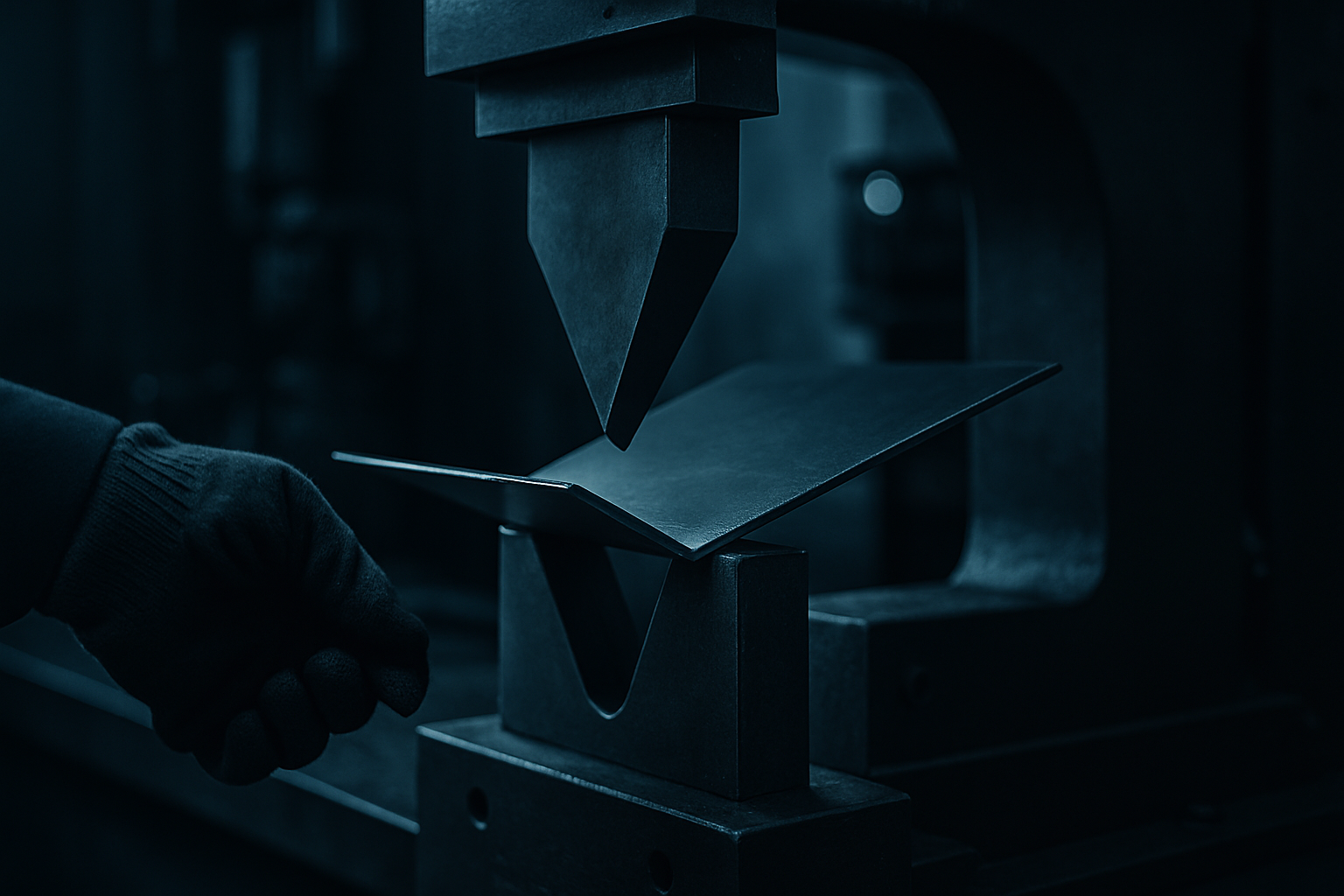

METAL SHEET PRESS WORK

PLATING & ELECTROPLATING

PAINT SHOP & POWDER COATING

MACHINE SHOP

FABRICATION SHOP