Industrial Solutions for Modern Manufacturing

Explore our comprehensive range of industrial services and engineering expertise.

At MFC, we provide custom rubber moulding services for industrial applications requiring flexibility, sealing, insulation, and vibration resistance. Our moulded rubber parts are produced with precision, durability, and material integrity, built to perform under pressure.

1. High-Performance Rubber Components

We manufacture custom rubber parts designed to absorb shock, resist heat and chemicals, and maintain flexibility, even in harsh environments.

2. Multiple Moulding Techniques

We offer a variety of moulding methods based on part complexity and production volume:

- Compression Moulding

- Transfer Moulding

- Injection Moulding

Each process is selected to ensure cost-efficiency, part strength, and surface quality.

3. Material Versatility

We work with a range of high-grade rubber compounds including:

- Natural Rubber (NR)

- Nitrile (NBR)

- EPDM

- Neoprene

- Silicone

- Fluorocarbon (Viton)

Each material is chosen based on temperature range, chemical exposure, mechanical load, and environmental conditions.

4. Part Types & Applications

We produce rubber parts such as:

- Gaskets & Seals

- Vibration Mounts

- Bushings & Grommets

- Rubber Pads & Stoppers

- Insulation Sleeves

Applications span across:

- Automotive

- Construction Equipment

- Electrical Systems

- HVAC

- General Manufacturing

5. Precision Tooling & Prototyping

We assist in the design and development of custom moulds, supporting low to high-volume production and prototyping for design validation.

6. Dimensional Accuracy & Tolerances

All moulded parts are manufactured to tight tolerances with clean edges, uniform wall thickness, and material integrity guaranteed.

7. Adhesive Bonding & Overmoulding

We also offer rubber-to-metal bonding and overmoulding for parts that require structural reinforcement or dual-material layering.

8. Resistance to Harsh Conditions

Our rubber products are designed to resist abrasion, oil, UV rays, moisture, and extreme temperatures, ensuring long service life.

9. Quality Testing & Inspection

Each batch undergoes hardness (durometer) testing, visual inspection, and dimensional checks to meet required standards.

10. From Design to Delivery

MFC is your trusted partner for reliable, industrial-grade rubber moulding solutions. We’re ready to turn your design into a functional, high-quality product, fast.

Related Posts

RUBBER MOULDING

MAINTENANCE SERVICES

FOUNDRY WORKS

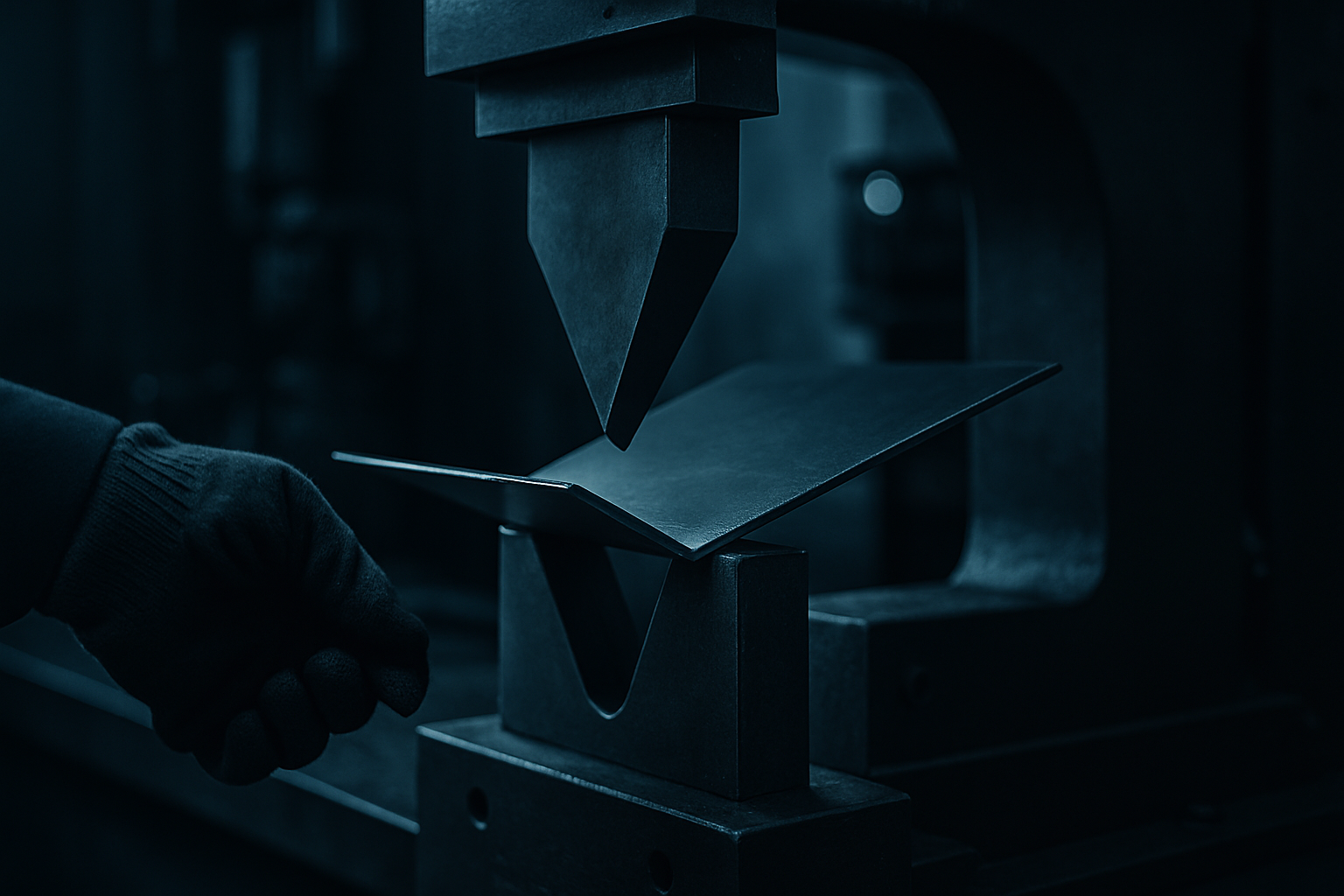

METAL SHEET PRESS WORK

PLATING & ELECTROPLATING

PAINT SHOP & POWDER COATING

MACHINE SHOP

FABRICATION SHOP