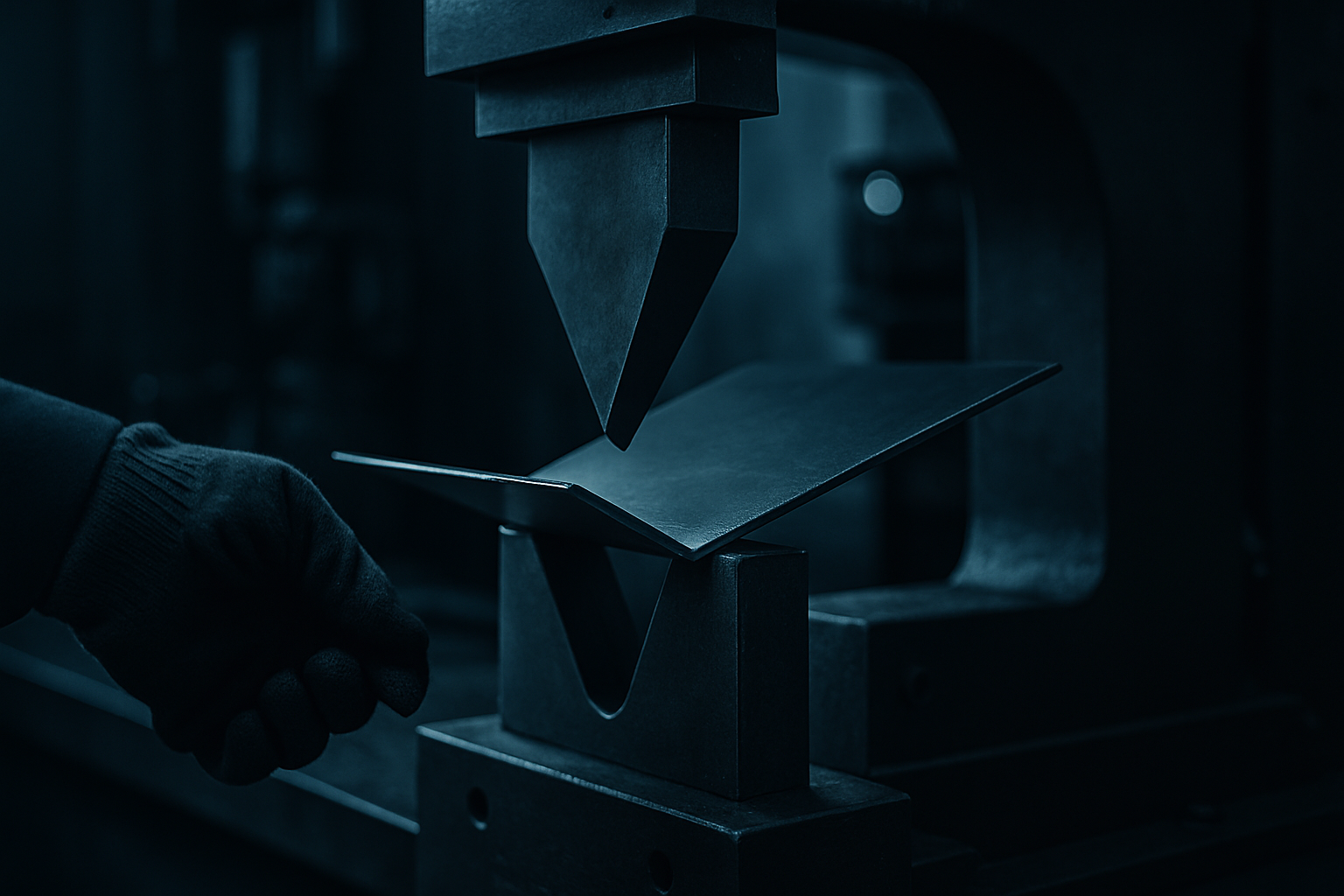

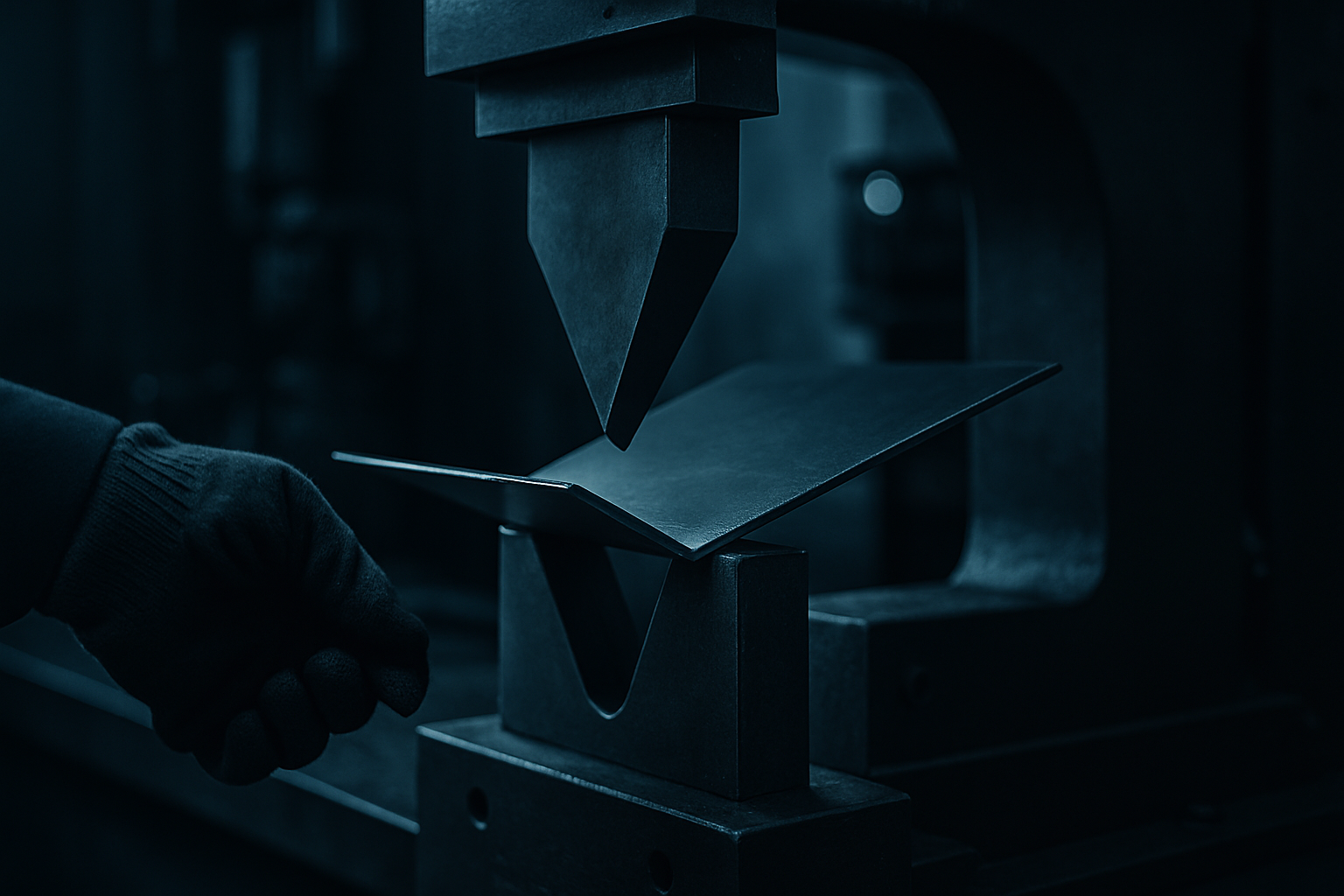

Precision Sheet Pressing

Accurate pressing for custom sheet metal components and assemblies

At MFC, our sheet metal division offers precision press work solutions for industrial and commercial applications. We handle a wide range of metal forming processes with high accuracy and repeatability, from simple brackets to complex enclosures, delivering consistent quality and durability.

1. Precision Sheet Forming

We specialize in sheet metal forming using hydraulic and mechanical presses, ensuring clean edges, uniform thickness, and accurate dimensions for every part we produce.

2. Versatile Forming Techniques

Our capabilities include:

- Punching

- Bending

- Deep Drawing

- Blanking

- Progressive Die Stamping

3. Wide Range of Materials

We work with a variety of materials such as:

- Mild Steel

- Galvanized Steel

- Stainless Steel

- Aluminum

- Copper

- Brass

4. Custom Dimensions & Tolerances

From thin gauge to heavy-duty sheets, we form parts with tight tolerances and custom specifications, based on your engineering drawings or prototypes.

5. Capacity & Applications

We process components ranging from 0.5mm to 6mm thickness, serving sectors like:

- HVAC

- Electrical Enclosures

- Construction Hardware

- Automotive Parts

- Machinery Panels

6. Integrated Assembly Options

We offer spot welding, riveting, and basic assembly services to deliver semi-finished or finished products ready for installation or final packaging.

7. High Efficiency & Repeatability

Using automated feeding systems and precision dies, we ensure high-speed production with repeatable accuracy, ideal for bulk quantities and tight delivery schedules.

8. Surface Treatment Ready

All components are prepared for surface treatments such as powder coating, electroplating, or anodizing, either done in-house or coordinated with finishing departments.

9. Technical Support & Die Design

We assist with tooling design, die manufacturing, and prototype testing, ensuring smooth transition from concept to production.

10. Built for Reliability

Our metal press work is trusted by manufacturers and contractors who value reliability, consistency, and cost-effectiveness in every order. Contact us to discuss your sheet metal needs today.

Related Posts

RUBBER MOULDING

MAINTENANCE SERVICES

FOUNDRY WORKS

METAL SHEET PRESS WORK

PLATING & ELECTROPLATING

PAINT SHOP & POWDER COATING

MACHINE SHOP

FABRICATION SHOP