High-Precision Machining Solutions

Advanced CNC and manual machining for accurate and efficient part production.

At MFC, our machine shop offers high-precision machining solutions for complex components and tight-tolerance requirements. With a combination of CNC and conventional machines, we serve various industries with speed, accuracy, and technical expertise.

1. Precision Machining Solutions

We provide machining services for parts requiring exact dimensions, clean finishes, and high functionality, whether for prototypes or production batches.

2. CNC & Conventional Equipment

Our workshop includes:

- CNC Turning & Milling Centers

- Lathe Machines

- Drilling & Tapping Machines

- Surface & Cylindrical Grinding Machines

- Boring Machines

This allows us to work on both small intricate parts and larger industrial components.

3. Materials We Handle

We machine a variety of materials, including:

- Mild Steel

- Alloy & Carbon Steel

- Aluminum & Copper

- Stainless Steel

- Cast Iron

- Brass & Bronze

We also accommodate special alloys as per project needs.

4. Tight Tolerances & Surface Finishes

Our machining capabilities meet tolerances down to ±0.01 mm, with surface finish options ranging from roughing to mirror polishing, depending on your application.

5. Applications Across Industries

Machined parts produced by MFC are used in:

- Oil & Gas Components

- Valves & Fittings

- Shafts & Gears

- Automotive & Transport

- Mechanical Assemblies

6. Prototype to Mass Production

We support single-piece machining, short-run prototyping, and mass production, adapting our workflow based on quantity and complexity.

7. CAD/CAM Integration

We use advanced CAD/CAM software to program and simulate parts before manufacturing, ensuring efficiency, accuracy, and fewer errors.

8. In-House Tooling & Fixtures

Our team designs and fabricates custom jigs, fixtures, and tooling in-house to enhance production quality and reduce setup time for repeated jobs.

9. Quality Control & Inspection

Every machined part goes through dimensional checks, surface inspections, and functional testing using tools like Vernier calipers, micrometers, and dial gauges.

10. Your Machining Partner

From one-off precision parts to large-scale components, MFC is your reliable partner for all machining needs. Let’s bring your mechanical designs to life with accuracy and speed.

Related Posts

RUBBER MOULDING

MAINTENANCE SERVICES

FOUNDRY WORKS

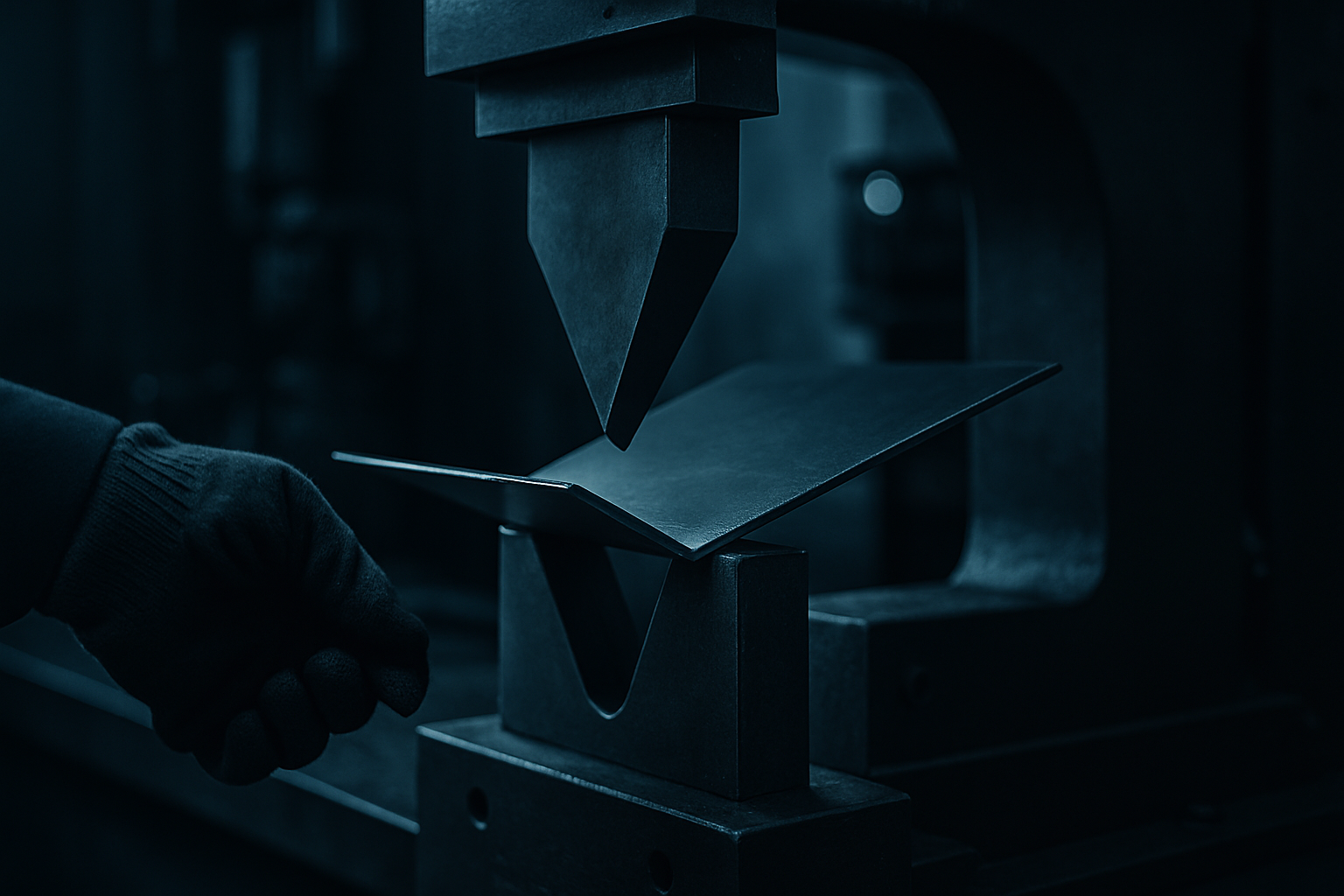

METAL SHEET PRESS WORK

PLATING & ELECTROPLATING

PAINT SHOP & POWDER COATING

MACHINE SHOP

FABRICATION SHOP