Industrial Forging Solutions

Custom forged components built for strength, reliability, and high-temperature applications.

At MFC, we specialize in precision hot forging for various industrial applications. Our forged components are known for their strength, durability, and dimensional accuracy, making them ideal for high-stress environments such as construction, transportation, and heavy machinery.

1. High-Strength Forged Components

MFC delivers precision hot forging solutions designed for high-load, high-temperature applications. Our forged parts are engineered for performance, reliability, and long service life, even in the most demanding conditions.

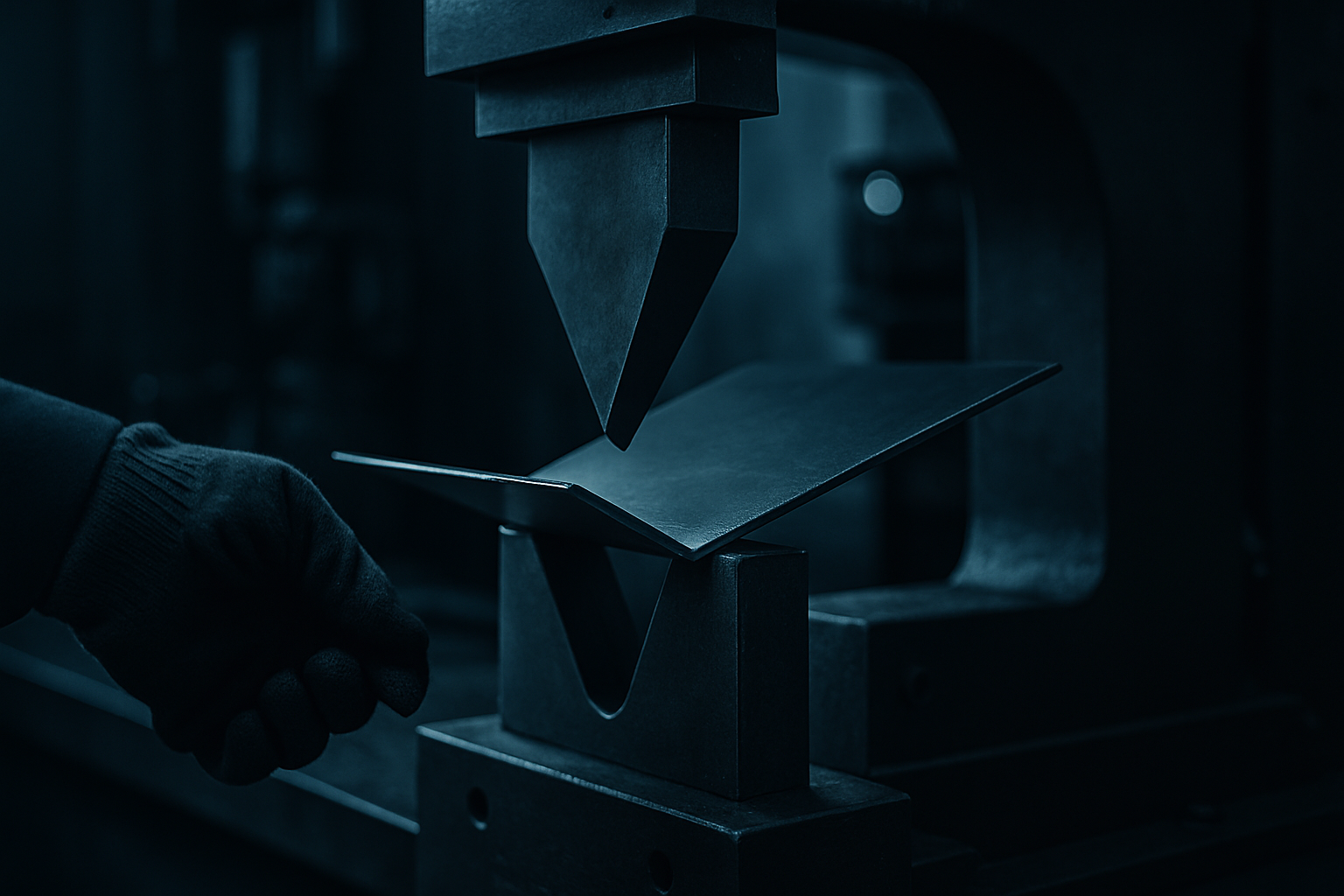

2. Forging Unit

We operate open-die forging systems capable of producing components that range from simple shapes to large, complex geometries. This process allows us to meet highly customized industrial requirements with flexibility and consistency.

3. Custom Shapes & Sizes

From shafts and rings to flanges and fasteners, we manufacture components in various shapes and sizes based on detailed CAD drawings or prototypes. This ensures perfect compatibility with your equipment and systems.

4. Capacity & Industry Applications

We forge parts ranging from 50 grams up to 5 kilograms per piece. Our forged components serve key industries such as:

- Oil & Gas

- Construction Equipment

- Transportation & Rail

- Power Generation

- Mining & Heavy Machinery

5. Heat Treatment & Finishing

To ensure optimum performance, we offer complete post-forging processes, including normalizing, annealing, quenching, tempering, and CNC machining, delivering a ready-to-install product.

6. Certified Quality Control

All forged components undergo stringent quality control, including dimensional inspections, material testing, and surface analysis, ensuring compliance with ISO and industry-specific standards.

7. Fast Turnaround & Scalability

Whether you're producing a prototype or a large production batch, MFC ensures efficient processing, quick delivery, and scalable manufacturing solutions.

8. Why Choose MFC Forging?

With over 30 years of experience, advanced technology, and a dedicated technical team, MFC has become a trusted name in the forging industry, capable of handling projects of any scale or complexity.

9. Request a Custom Quote

Need high-precision forged parts for your next project? Our team is ready to provide tailored solutions based on your specifications. Contact us today to request your custom quote.

Related Posts

RUBBER MOULDING

MAINTENANCE SERVICES

FOUNDRY WORKS

METAL SHEET PRESS WORK

PLATING & ELECTROPLATING

PAINT SHOP & POWDER COATING

MACHINE SHOP

FABRICATION SHOP